Services

Lean Manufacuring

Our facility has developed a Continuous Improvement culture to keep our costs under control and pricing competitive. SAAR Corporation is currently implementing 5S and other Lean & 6-Sigma processes across our entire facility.

Kanban

Let SAAR Corporation assist you in meeting your operational goals by setting up Kanbans (safety stock) at our facility. Product can be delivered at desired rate (daily, weekly, monthly) to align with the production schedule at your facility. We can accommodate orders coming in via fax, e-mail, or set-up an electronic order release system between our facilities.

Warehousing

Warehousing for your material is available on the West and East Coast of the United States. We can stock material in Farmington, CT or Santa Ana, CA to minimize freight costs and transit times.

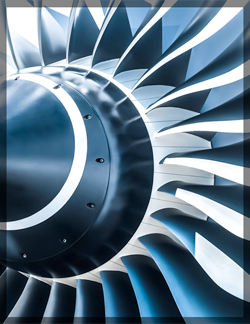

Aerospace

SAAR Corporation has been providing precision manufacturing services to the Aerospace and Commercial Aircraft industries for more than fifteen years. Many of our engineers have spent decades working in this industry and understand what it takes to be successful.

Over the past 15 years we have earned the respect of our customers and continue to grow our business. Our dedication to consistent quality, on-time delivery, and customer service has allowed us to continuously meet our customer’s challenging requirements. We are experienced in working with many exotic materials including High Temperature Alloy, Titanium, Inconel, Stainless Steeel, Aluminum, and Hastelloy. Utilizing our core manufacturing processes of 3&5-axis machining, turning, and other critical finishing operations, we’ve been awarded many difficult to manufacture Aerospace components that our competitors have failed to produce.

Our dynamic facility is set-up to meet your needs on everything from rapid proto-types to high volume production runs.

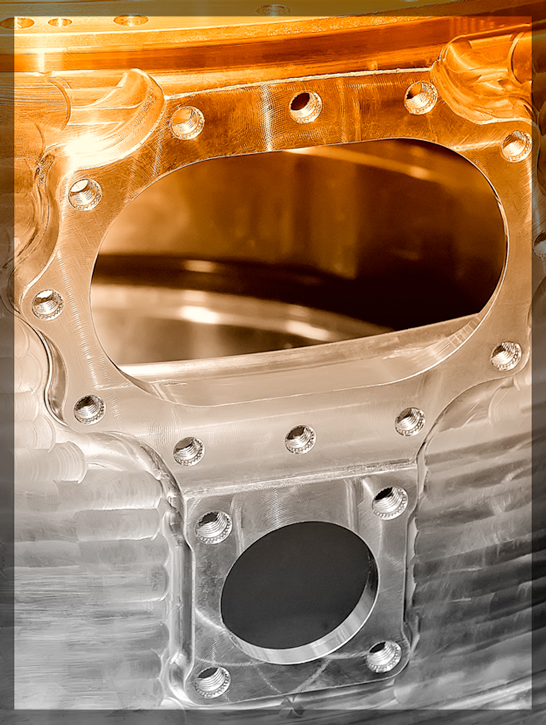

Fire Arms

SAAR Corporation is a Federally Licensed, contract manufacturer of precision firearms components. We have been a key supplier to many of the leading gun manufactures for the past five years.

Our facility is set-up to meet your needs on everything from engineering support, proto-type machining, high volume production, and value-added assembly.

Our dedication to consistent quality, on-time delivery, and customer service has allowed us to continuously meet our customer’s tough demands. Utilizing our core processes of 3&5-axis CNC turning and milling, we’ve developed and manufactured numerous components for pistols, rifles, machine guns, and other black firearms.

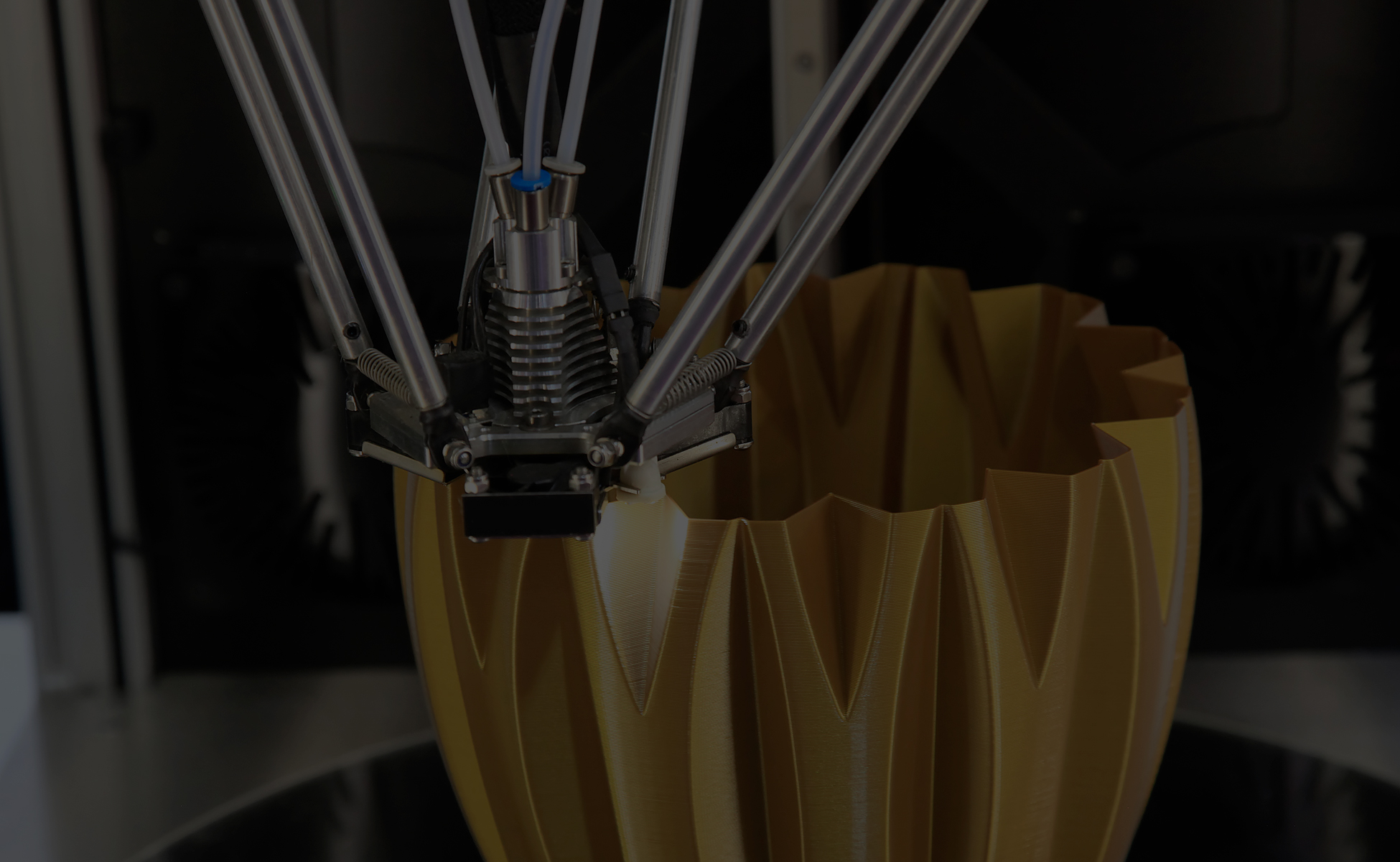

Medical

SAAR Corporation is a premier manufacturer of medical implant components and surgical devices. In our state-of-the-art manufacturing facility we produce critical components, which are used in orthopedic and spinal surgeries. By having the latest 3&5-axis CNC turning and milling equipment it allows us to manufacture complex part geometries in virtually all materials including titanium, stainless steel and plastics.

For years SAAR has remained dedicated to provide our customers in the medical field with our knowledge and experience to help improve value and manufacturability. SAAR has been a key manufacturing partner providing design assistance and efficient component production.

Our dynamic facility is set-up to meet your needs on everything from rapid proto-types to high volume production runs. We can supply you with individual machined components or provide full turn-key solutions.

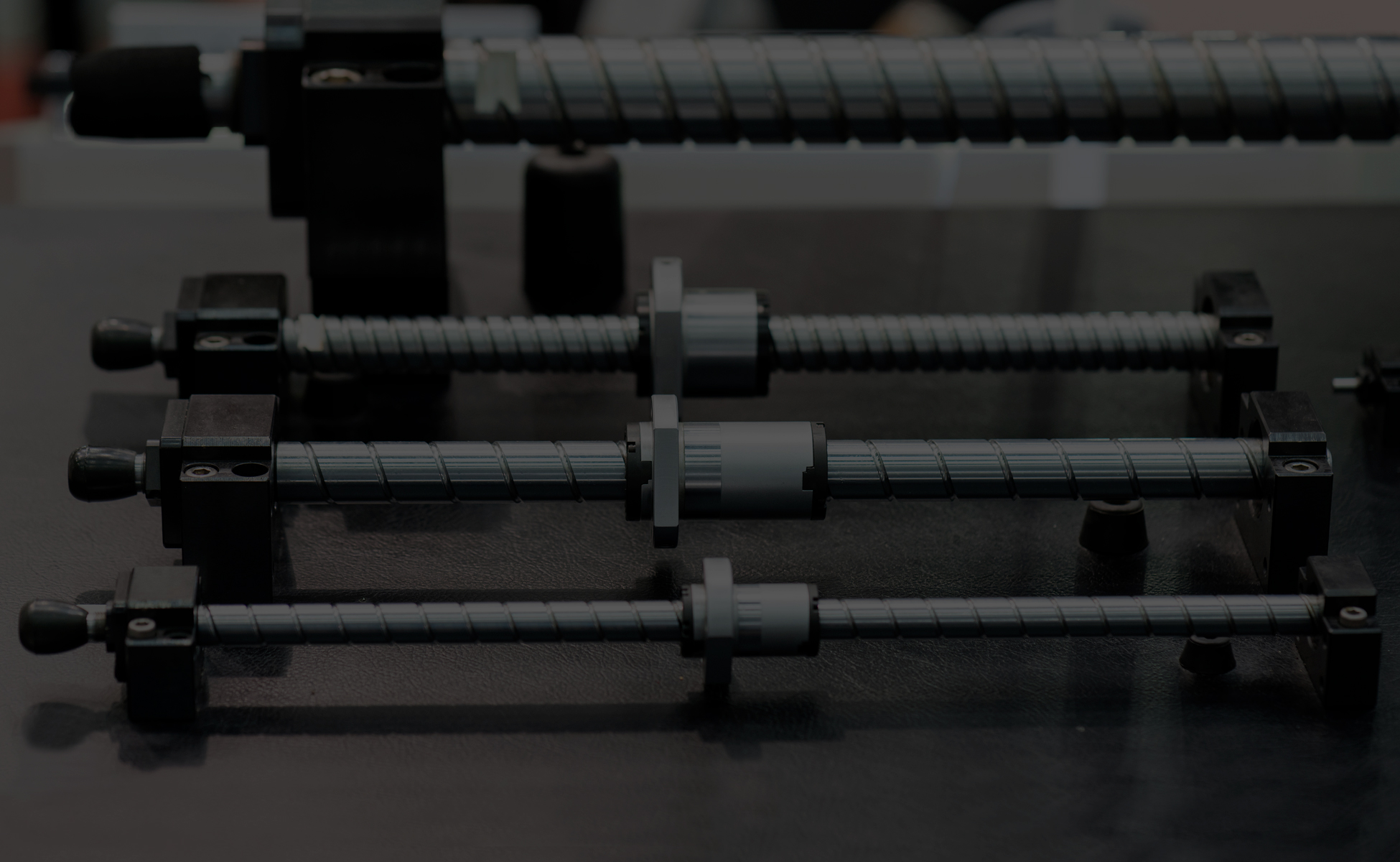

Oil | Gas | Heavy Products

SAAR Corporation is very experienced in producing precision machined components for the Automotive and off-road vehicle industry. With our state-of-the-art 3&5 axis CNC milling and turning centers we are capable of producing:

– Turbine blades

– Impellers

– Compressor housings

– Custom valve bodies

– Steering and suspension components

– Other critical components

We’ve manufactured a number of components for our customers working with materials such as High Temperature Alloy, Titanium, Inconel, Carbon Steel, Stainless Steeel, and Aluminum. We are recognized in many industries for our ability to produce components with very complex design specifications and very tight tolerances. With our Lean & Continuous Improvement culture and experienced Engineering staff we can provide excellent turnaround and competitive pricing.

Automotive ServicesOur dynamic facility is set-up to meet your needs on everything from rapid proto-types to high volume production runs.